The Role of Process Flow Diagrams in Clothing Decoration

The Essence of Process Flow Diagrams in Apparel Design

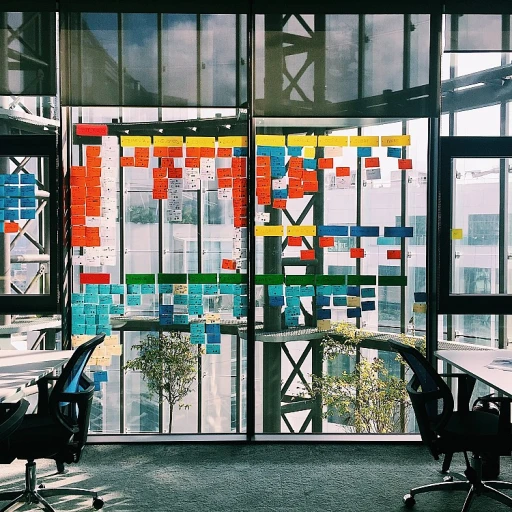

Process flow diagrams are vital tools that play a crucial role in the apparel industry's intricate world, where the synergy of art and science comes together. These diagrams provide a structured representation of the sequence of steps involved in the garment design and manufacturing process, offering invaluable insights into each stage—from initial design concept to final product development. The effectiveness of process flow diagrams lies in their ability to streamline communication and facilitate an efficient understanding of the production process across departments. For instance, in the manufacturing of cotton textiles, a detailed flowchart can help illustrate the transition from raw material to finished garment, highlighting key production stages such as fabric cutting, pattern making, assembly, and quality control. By visualizing these processes, a business can pinpoint potential bottlenecks and optimize garment manufacturing for better quality and efficient production. Process flow diagrams are especially beneficial in ensuring that quality control measures are uniformly applied throughout the textile manufacturing stages. They offer a visual checkpoint system that allows teams to identify and address errors early in the production chain. Furthermore, integrating advanced tools such as tech packs and flow diagrams into the design process ensures that fashion products meet the target market's demands while maintaining the desired standards of quality and design. To deepen your understanding of how process flow diagrams foster effective change management in the clothing decoration process, delve into the nuances of objective analysis in change management, where systematic evaluation transforms operational workflows for better business outcomes.Identifying Key Stages in the Clothing Decoration Workflow

Crucial Phases in Workflow Transformation

Understanding the workflow of clothing decoration requires a keen eye for detail, especially when diving into the intricate phases of the garment manufacturing process. Each stage plays a pivotal role in ensuring the final fashion product meets the desired quality and design standards. To streamline the production process, the fashion industry often relies on process flow diagrams and flowcharts. These visual representations help outline the sequence of steps involved, from initial design to the completion of textile manufacturing.- Design and Development:

- Starts with a clear vision for the fashion design. Designers create tech packs that include every detail about the garment.

- The development process includes pattern making, which requires precision to ensure each piece fits cohesively.

- Pre-Production Planning:

- This phase involves sourcing fabrics and materials, crucial for quality control.

- Manufacturing teams establish timelines and prepare flowcharts to manage workflow efficiently.

- The creation of a tech pack ensures every aspect of the design process is documented and communicated.

- Production and Cutting:

- Where the real action begins, involving the cutting of fabric according to pattern specifications.

- A meticulous flow diagram or production process flowchart helps monitor garment assembly and ensure quality.

- Quality Control and Garment Finishing:

- Ensures the final product adheres to the highest standards before reaching the market.

- Regular checks are vital to avoid any compromises in the finished product.

- Final Review and Feedback:

- Feedback is collected for continuous improvement and future business process optimization.

- Effective changes in the clothing decoration workflow can be further analyzed through an understanding of the impact of culture score.

Managing Change in the Clothing Decoration Process

Successfully Navigating Transitions in Apparel Customization

Change management is an integral component of the clothing decoration workflow, as it ensures an adaptive process that maintains efficiency and quality. Within garment manufacturing, the integration of new technologies and innovative designs prompts necessary shifts in how businesses approach production. Clear guidelines become essential for mitigating disruption and maintaining fluid operations during these transitions.

The first step in managing change is to identify the existing processes through detailed flowcharts and diagrams. These tools provide a comprehensive overview of the stages involved, from the initial design process to the production of the final fashion product. Such visual aids help pinpoint areas that require adjustments to accommodate new developments in fashion trends or textile manufacturing techniques.

To assist in managing these changes, it's critical to utilize flexible tools and techniques that support effective change management. This could include employing tech packs and process flow diagrams to document process changes and track their impact on the overall workflow. These resources are instrumental in planning and executing changes with precision while ensuring that quality control remains a priority throughout the garment's lifecycle.

Furthermore, fostering a culture of communication and collaboration within teams encourages successful change implementation. Regular meetings and feedback sessions can address any issues that arise and ensure that all parties involved in the garment production process are on the same page. Engaging with employees at every level provides an opportunity to gather insights and refine the change strategies for a more seamless transition.

Embracing innovation within the textile and apparel industry not only keeps businesses competitive but also fuels creativity in fashion design. For those interested in diving deeper into strategies for managing change effectively, exploring the power of talent mapping in change management can offer valuable insights into aligning personnel skills with new processes.

Tools and Techniques for Effective Change Management

Effective Strategies for Navigating Transformations

- Garment Manufacturing Adjustments: Changing trends in fashion and textiles often require adaptations in garment manufacturing workflows. Keeping track of the process flow and identifying areas that need adjustments can help in the successful transition from old methods to new, more efficient practices.

- Utilizing Flow Diagrams: Flow diagrams act as visual guides for understanding and managing the production process. They enable teams to pinpoint potential issues in the fabric cutting or pattern making stages and adjust accordingly. Such diagrams serve as invaluable tools for highlighting areas in need of change.

- Quality Control Enhancements: In the fast-paced world of fashion design, maintaining quality is paramount. Implementing thorough quality control measures at every stage, from pre-production to the final textile manufacturing step, ensures high standards are met consistently. A well-documented quality control process flowchart can aid in spotting inefficiencies and advocating for necessary changes.

Applying Tools and Techniques in Process Flow Management

To enhance the efficiency of the garment manufacturing journey, various tools and techniques can be integrated into the process. These tools support business processes by providing detailed overviews through flowcharts and diagrams, allowing for better monitoring and intervention when needed.

- Process Flowchart Utilization: By utilizing comprehensive flowcharts, teams can visualize the progression of the garment manufacturing process. These charts aid in recognizing unsuccessful strategies and refining production methods.

- Tech Packs as Planning Tools: Detailed tech packs delineate every aspect of the fashion product development process from start to finish. They ensure cohesive communication and aid in managing transitions effectively, while maintaining consistency across design and production teams.

- Fashion Product Development Techniques: Embracing innovative techniques in product development frequently results in improved productivity. By employing the latest design process methods and maintaining a keen eye on pattern making, businesses can streamline their workflow for better results.

Case Studies: Successful Change Management in Clothing Decoration

Real-Life Success Stories in Change Management

Embracing change in the garment manufacturing sector is no small feat. By looking into real-world applications, the effectiveness of managing transition using process flowcharts and other innovative techniques becomes evident. Below are some illuminating examples.- Streamlining Production with Flow Diagrams: One notable instance involved a renowned fashion brand that utilized process flow diagrams to reimagine its production line. By mapping out each step, from cutting the fabric to the final quality control, they reduced bottlenecks within the textile manufacturing process. The flowchart provided a clear visual representation that facilitated communication across departments, leading to a more cohesive business process.

- Boosting Quality Control: Another example highlights an organization that revamped its garment decoration by emphasizing quality assurance. By deploying a robust chart textile system to oversee the design process, they achieved higher customer satisfaction. Deploying a quality-focused pattern making strategy, aligned with tech packs, further enhanced their fashion product quality and reliability.

- Enhanced Collaboration through Tech Packs: A transformative approach was witnessed in a company that managed its product development via detailed tech packs. These comprehensive documents ensured that every design, from pre-production to the final garment, met high standards. This move not only improved their internal workflow but also streamlined collaboration with external partners, facilitating a smoother production process.

Future Trends in Clothing Decoration Workflow Management

Emerging Innovations and Trends

In the dynamic world of clothing decoration, the future holds a myriad of possibilities for workflow management. As technology evolves and customer preferences shift, businesses within fashion design and textile manufacturing are continually looking for ways to streamline their production processes.- Seamless Integration with Technology: The integration of AI and machine learning into garment manufacturing is set to revolutionize operational efficiency. By leveraging these technologies, businesses can optimize their process flow, predict design trends, and refine quality control measures.

- Sustainability Initiatives: There is a growing emphasis on sustainable fashion products. As part of this movement, companies are exploring eco-friendly materials and zero-waste production techniques in the garment making and design processes.

- Customization and Personalization: The rise of digital printing and 3D pattern making allows for greater customization in fashion design. It empowers consumers to personalize textiles, garments, and designs, which necessitates adaptive business processes.

- Smart Tech Packs: The use of advanced tech packs is becoming prevalent. These tools help manage pre-production stages efficiently by offering detailed, interactive flowcharts and charts for communicating design specifications and production processes.

- Collaborative Platforms: Collaboration is key in the fashion industry. Platforms that facilitate design and production synergy, aiding the flow of creative ideas and business intelligence across teams, are redefining the traditional process flowchart.