-large-teaser.webp)

The Basics of a Yamazumi Chart

Grasping the Concept of a Yamazumi Chart

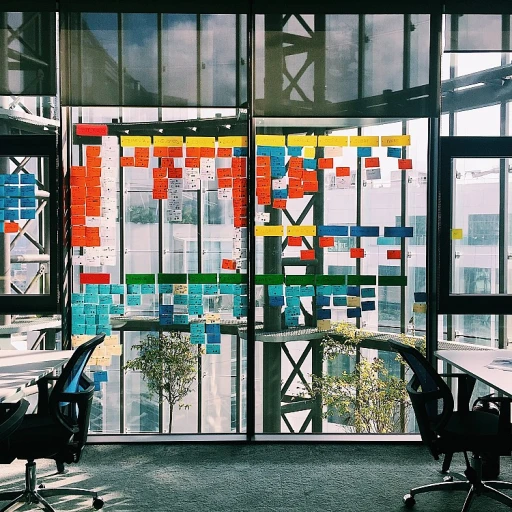

If you're delving into change management, understanding the Yamazumi chart is crucial. It's a tool that is widely used in lean manufacturing and continuous improvement efforts. Essentially, a Yamazumi chart is a type of stacked bar chart that helps visualize the distribution of tasks and time across a process. It offers an insightful way to analyze cycle times, process steps, and identify bottlenecks in your workflow. To break it down further, a Yamazumi chart is a visual representation where each bar displays a step in a process. These bars are stacked to exhibit each task's work content, giving you a clear picture of how time-consuming each cycle time is in your production line. Lean tools like the Yamazumi chart address challenges in balancing workloads, helping standard work processes to become more efficient. The process starts by gathering data on cycle time and takt time for every task involved in producing a product. This data is then translated into a bar chart that makes it easier for teams to comprehend where improvements are necessary. Whether you choose to create Yamazumi charts using traditional methods or tools like Excel, the ultimate goal remains to simplify analysis and foster continuous improvement. This method is particularly effective in environments that demand lean sigma and lean manufacturing practices, where time and efficiency are of the essence. With the Yamazumi chart, your team can pinpoint areas needing improvement, simplifying the identification of tasks that consume excessive time or energy. And, as you consider implementing Yamazumi charts in your change management workflows, you might also want to explore other methods of enhancing business processes, such as enhancing business processes with six sigma. This integrative approach can ensure a well-rounded improvement strategy.Implementing Yamazumi Charts in Change Management

Initiating Yamazumi Chart Deployment

The implementation of yamazumi charts in change management requires a structured approach. When integrating this tool into a project, it's crucial to follow a methodical process that aligns with the principles of lean sigma. A well-crafted plan ensures that resources are utilized effectively and results are maximized.

Data Collection and Preparation

Before creating the yamazumi chart, collect comprehensive data regarding the cycle times and process steps of existing workflows. This data serves as the foundation for your chart, highlighting areas where cycle time can be optimized. Remember, accurate data collection is paramount to the success of any improvement initiative.

Designing the Chart

Begin by plotting activities and tasks as bars on the yamazumi chart. This stacked bar visualization provides clarity on the current state of process time distribution within the workflow. Using tools like excel can assist in managing the intricacies involved in calculating and displaying data efficiently.

Analyzing and Identifying Opportunities

With the chart in hand, perform an analysis to identify tasks or activities with excessive work content or those that fall short of standard work requirements. This analysis is the first step towards uncovering potential areas for lean manufacturing enhancements. By assessing each task's contribution to the overall cycle, you'll pinpoint opportunities for improvement.

Implementing Changes and Training

Successful implementation goes beyond just plotting data. It involves training teams on interpreting charts and employing lean tools for continuous improvement. Training ensures everyone is aligned with the new processes, promoting a seamless transition and fostering a culture of improvement.

Iterative Improvement and Review

Yamazumi charts should be revisited periodically as part of an ongoing cycle of continuous improvement. Regularly updating the charts with fresh data aids in maintaining momentum and adapting to evolving product mixes or operational strategies.

For a deeper dive into enhancing processes with six sigma techniques, explore enhancing business processes with six sigma.

Benefits of Using Yamazumi Charts

Unveiling the Benefits of Yamazumi Charts

In the realm of change management, especially within environments embracing lean and continuous improvement, the Yamazumi chart serves as a powerful tool. This stacked bar chart, which vividly represents work content and cycle times, offers several notable benefits.- Visual Clarity: Yamazumi charts provide an easy-to-understand visual representation of tasks and activities across different process steps. Each bar, representing a task or a group of tasks, helps teams identify imbalances in workload, making it easier to implement improvement tools.

- Data-Driven Decisions: By utilizing lean tools like Yamazumi charts, organizations can perform in-depth analysis of process times. This data enables companies to make informed decisions and implement lean sigma strategies effectively.

- Process Improvement: Understanding cycle times using Yamazumi charts allows teams to pinpoint bottlenecks and areas for improvement. These insights facilitate the adoption of standard work practices and continuous improvement measures, ultimately reducing cycle times and enhancing process efficiency.

- Enhanced Team Collaboration: Implementing a chart Yamazumi encourages team involvement in the problem-solving process. Team members can collectively explore solutions, which promotes a culture of cooperative engagement and shared responsibility in achieving lean manufacturing goals.

- Flexibility in Application: Whether integrating with existing work methods or adapting to variations in product mix, Yamazumi charts are adaptable. These charts can be customized to reflect changes in takt time, allowing managers to respond swiftly to new demands and market conditions.

Challenges and Solutions

Overcoming the Complexities of Implementing Yamazumi Charts

Implementing yamazumi charts in change management is not without its challenges. While these tools offer powerful insights into process improvement, there are obstacles that must be navigated thoughtfully. One of the primary challenges is the initial training required for interpreting and creating yamazumi charts effectively. Understanding how to plot different work activities and tasks into a stacked bar chart necessitates a sound grasp of lean manufacturing principles and cycle time analysis. Without proper training, teams might misrepresent data, resulting in ineffective analysis and misinformed decisions. Moreover, collecting accurate data is crucial yet often difficult. Ensuring that all time spent on tasks is recorded precisely demands vigilance and consistency from every team member. It's essential to foster a culture of transparency and accountability where everyone values the accuracy of the recorded process time. Another potential hurdle is resistance to change. Teams accustomed to traditional modes of operation may perceive yamazumi charts as extra work instead of tools for improvement. To combat this, it's vital to demonstrate the tangible benefits that these charts bring, such as identifying bottlenecks and highlighting areas for continuous improvement. Involving team members in the discussion about product mix and task prioritization can also help gain buy-in. Technical issues, like software compatibility and data integration with systems like Excel, may present further difficulties. Organizations need to ensure that the right tools are in place to facilitate seamless data management and that staff are comfortable using them. Steps to counter these challenges include comprehensive training programs that not only focus on the technical aspects of yamazumi chart creation but also emphasize the broader context of lean sigma and takt time in achieving efficiency. Regular feedback sessions where employees can voice concerns and suggest improvements to the process steps can also aid in easing the transition. Lastly, fostering an environment that encourages continuous improvement will allow for adaptive methodologies where teams can iteratively improve how they utilize yamazumi charts as improvement tools. By addressing these challenges head-on, organizations can unlock the full potential of yamazumi charts to optimize cycles and work content effectively.Case Studies: Success Stories

Success Stories Using Yamazumi

The application of Yamazumi charts in change management has produced notable success stories across various industries. These success stories highlight the charts' role in minimizing cycle times and streamlining processes to boost overall efficiency. Here, we delve into a few examples illustrating the transformative power of Yamazumi implementation.- Lean Manufacturing Excellence: In the realm of lean manufacturing, a company focused on automotive parts leveraged Yamazumi charts to improve their assembly line efficiency. By reorganizing work content and redistributing tasks according to takt time, they significantly reduced their process time. The detailed analysis provided by the charts enabled the team to identify bottlenecks and optimize work distribution, resulting in a 20% reduction in cycle times.

- Enhanced Product Mix Strategy: A consumer electronics firm sought to improve their product mix strategy to better respond to market demands. By examining their work activities with Yamazumi charts, they could better manage their product lines and adjust the task sequence for optimal performance. This strategic use of data allowed for a more balanced approach that aligned with their business goals.

- Training and Development Improvement: In a large healthcare organization, Yamazumi charts were implemented as part of their training program. The visual depiction of task cycles helped outline standard work for new employees, improving onboarding processes. As a result, the training cycle time was cut by 10%, enhancing staff throughput and patient care quality.

- Continuous Improvement in Operations: An organization dedicated to retail logistics made strategic use of Yamazumi as a part of their ongoing improvement initiatives. By adopting a continuous improvement mindset, they continually refined their process steps using stacked bar analysis to visualize and address inefficiencies. This proactive approach reduced lead times and increased customer satisfaction.

Tips for Maximizing the Impact of Yamazumi Charts

Enhancing the Effectiveness of Yamazumi Charts

Successfully utilizing a yamazumi chart in change management requires a thoughtful approach and some crucial strategies. Whether you're working on lean manufacturing processes or aiming for continuous improvement, here are some tips to maximize the impact of your charts:Engage in Thorough Training

- Comprehensive training is essential to make sure everyone understands yamazumi charts and how to interpret the data they present.

- This includes understanding process time, cycle time, and how these elements relate to your specific workflow.

- Use examples that focus on your organization's product mix and work content.

Integrate Yamazumi Charts with Other Lean Tools

- Combining yamazumi with other lean sigma tools, such as takt time calculations and standard work sheets, can offer a more robust analysis.

- Using these tools together helps in identifying bottlenecks in process steps and aligning those with lean improvement efforts.

Utilize Digital Solutions

- While traditional yamazumi charts or bar charts provide significant insights, leveraging digital tools like Excel can enhance data analysis and visualization.

- Excel's features allow for a dynamic approach to modify stacked bar designs and refine visualization, thus providing more immediate insights.

Regularly Update and Review

- Yamazumi charts should not be static. Regular updates and reviews are crucial for reflecting any changes in cycle times or task assignments.

- Frequent iterations encourage more accurate reflections of process improvements and adjustments.

Encourage Collaboration and Feedback

- Encourage team collaboration to gather different perspectives on chart yamazumi data analysis.

- Feedback loops will highlight potential areas for improvement and ensure that everyone aligns with the improvement goals.