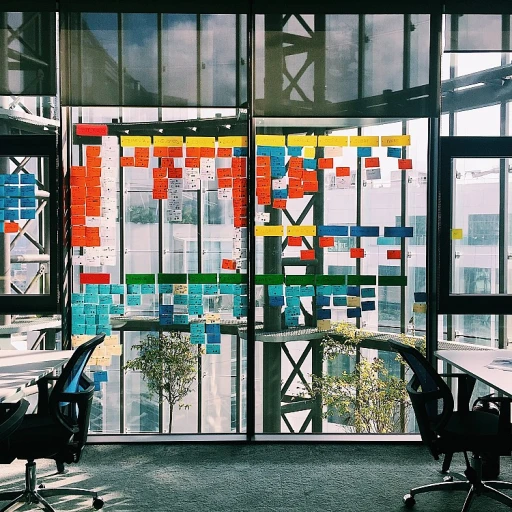

-large-teaser.webp)

Understanding Turnaround Planning

Grasping the Essentials of Turnaround Planning

Turnaround planning is a pivotal aspect of maintaining the efficiency and safety of a plant. It involves methodically scheduling and carrying out maintenance tasks during a shutdown, which is a highly complex operation. The turnaround process requires meticulous project management to minimize downtime and ensure a cost-effective execution.

Taking into account the effective project management plan is essential. This helps in organizing the scope of work and time management, which are indispensable for a successful turnaround. The planning phase establishes the groundwork, wherein the detailed strategic approach must encompass all aspects of the plant's operation and maintenance needs.

A turnaround planner must consider not only the sequencing of equipment maintenance but also the integration of safety protocols and the logistical organization of materials and resources. These efforts ensure that the shutdown turnaround progresses smoothly. The coordination of resources is crucial, as it involves harmonizing workforce, spare parts, and other pertinent elements within the critical path to facilitate real-time decision-making and adaptations during the execution phase.

The scope will typically cover inspections, repairs, upgrades, and various other maintenance activities. In this light, thorough work orders and attention to detail in the early planning stages can significantly reduce costs and optimize the overall turnaround management. As we shall explore further, the alignment of these elements ensures that turnaround scheduling becomes a streamlined operation rather than a bottleneck in the project timeline.

Key Elements of Scheduling

Prioritizing Safety and Time Constraints

The effectiveness of turnaround scheduling greatly hinges on managing safety protocols while respecting time constraints. This dual approach ensures that the plant and equipment are maintained without compromising the security and health of workers. By delineating a clear, realistic timeline, turnaround planners can mitigate risks and optimize workflow. The planning phase should integrate a comprehensive scope of work that encompasses all critical tasks and aligns with the scheduled shutdown period.Establishing a Clear Scope and Objectives

One of the cornerstones of successful turnaround scheduling is setting a well-defined scope. This ensures that all work orders are accounted for, and the turnaround process is streamlined. Maintenance managers and planners must coordinate to outline precise objectives, which guide the scheduling and execution phase. Clarifying the scope helps prevent scope creep, ensuring that unplanned activities do not disrupt the schedule and increase costs. This meticulous approach is indispensable for cost management and achieving a successful turnaround.Deploying the Critical Path Method

The critical path method (CPM) is a pivotal tool in the realm of turnaround scheduling. This technique aids in identifying the sequence of crucial and dependent tasks required to complete a project in the shortest time possible. By employing CPM, turnaround planners can foresee potential delays in the turnaround maintenance process and adjust the schedule accordingly to meet deadlines. This proactive approach ensures tasks are executed on time, preventing any cascading effects on subsequent activities.Integrating Real-Time Data and Technology

Incorporating real-time data into the scheduling process can dramatically enhance turnaround efficiency. With modern project management software, maintenance managers can monitor ongoing tasks and resource allocation. This facilitates quick adjustments to the schedule, reducing delays and improving project outcomes. The integration of technology in planning scheduling is a testament to the evolving nature of turnaround management. For further insights into effective strategies, explore the article on leading change in educational settings.Adhering to Best Practices in Turnaround Management

Finally, adhering to established best practices in turnaround management is imperative. This includes setting clear communication channels among all stakeholders, conducting exhaustive pre-turnaround reviews, and executing thorough post-turnaround assessments. By integrating these practices into the scheduling phase, organizations can enhance the safety, efficiency, and cost-effectiveness of shutdown turnarounds. The ultimate goal is to facilitate a seamless plant turnaround that adheres to both time and budgetary constraints.Challenges in Turnaround Planning

Common Obstacles in Turnaround Projects

In the realm of turnaround planning and maintenance, certain challenges can often impede successful project execution and management. These challenges can slow down processes, inflate costs, and compromise safety, leading to a domino effect that affects the entire plant operation. Recognizing these obstacles early can equip turnaround planners and maintenance managers to better prepare and respond efficiently.Scope Definition and Management

Defining the scope work of a turnaround project is pivotal, yet it's often one of the most poorly managed aspects. Without a clear scope, there's a risk of overextending resources or overlooking essential maintenance tasks. The scope must align with the plant's strategic objectives and must be well-communicated to all stakeholders. Focusing on a well-defined scope reduces uncertainties and helps in scheduling and execution.Effective Scheduling

Scheduling plays a crucial role in the shutdown turnaround process. It requires precise planning scheduling to ensure all activities are executed in real time, without unnecessary delays. Challenges arise when there's a lack of synchronization, resulting in bottlenecks or idle periods that can balloon costs and extend the timeline. Identifying the critical path in the turnaround schedule is essential to prioritize maintenance and mitigate delays.Resource and Equipment Management

The execution phase requires comprehensive management of resources and equipment. Insufficient resources or malfunctioning equipment can halt work orders, leading to delays in the turnaround schedule. Effective project management involves anticipating these needs and preparing contingencies to tackle unexpected shortages or breakdowns.Adherence to Safety Protocols

Safety is paramount in turnaround maintenance. Plant turnarounds involve high-risk activities, and any lapse in safety can lead to accidents, legal liabilities, and compromised worker well-being. Ensuring strict adherence to safety protocols is non-negotiable. Proper training, continuous monitoring, and enforcing best practices help in safeguarding both personnel and equipment.Controlling Costs

The cost of a turnaround project can spiral if not meticulously managed. Factors such as overtime pay, expedited shipping for parts, or penalties for late completion contribute to inflated budgets. Applying rigorous cost control measures during both the planning phase and execution phase can help keep financials in check and prevent cost overruns. For insights into how effective scheduling can mitigate these challenges, consider exploring crafting an effective project management plan, which is crucial in navigating the complexities of turnaround projects.Tools and Techniques for Effective Scheduling

Key Techniques for Managing Turnaround Scheduling

Scheduling is a crucial aspect of turnaround planning, and utilizing effective tools and techniques ensures the successful execution of the maintenance project. A well-developed schedule aids in managing resources, controlling costs, and minimizing shutdown times, ultimately leading to a safe and efficient plant turnaround.

- Critical Path Method (CPM): This technique helps to identify the longest sequence of dependent tasks from start to finish, allowing planners to systematically allocate resources and ensure timely completion of the turnaround maintenance.

- Integrated Work Order Management: By integrating work orders into the scheduling process, turnaround planners can streamline task assignments, prioritize critical scope work, and keep track of equipment availability and delivery schedules in real-time.

- Gantt Charts: An invaluable visual tool, Gantt charts provide a clear overview of the project timeline, demonstrating task dependencies and possible scheduling conflicts, which aids in optimizing the turnaround schedule.

- Resource Leveling: This technique ensures that required resources, such as labor and equipment, are optimized and evenly distributed across the project phases, preventing bottlenecks and over-allocation.

- Cost Control and Monitoring: Implementing a rigorous cost management process during the scheduling phase can prevent over-expenditure. Monitoring and analysing costs consistently throughout the turnaround process supports spending within budget limits.

Adopting these methodologies not only enhances scheduling precision but also aligns with industry best practices for turnaround management. Recognizing these techniques is essential in navigating the challenges that come with maintaining efficient shutdown turnarounds, ensuring that each phase of the turnaround is meticulously planned and effectively executed.

Case Studies: Successful Turnaround Implementations

Case Study Insights: Lessons from Turnaround Successes

Exploring real-world examples of successful turnarounds provides valuable insights into how various elements of planning and scheduling can work in tandem to achieve desired outcomes. In the dynamic world of plant maintenance and project management, analyzing past projects can offer a deeper understanding of the critical factors that contribute to a productive turnaround. Comprehensive Scope Definition One of the prominent features observed in successful turnaround projects is the clear definition of the scope of work. Precise scope planning allows for streamlined scheduling and ensures that all project phases, from shutdown to post turnaround, are executed efficiently. The scope defines the boundaries of what needs to be accomplished, aligning maintenance managers and turnaround planners on the objectives, thus minimizing misunderstandings. Prioritizing Safety and Compliance In any turnaround, safety takes precedence. Adherence to safety protocols and regulatory standards safeguards not only the workforce but also the plant's equipment and infrastructure. Projects, where safety was the focal point during the planning phase, often witness fewer accidents and incidents, contributing to uninterrupted workflow and time savings during execution. Efficient Scheduling with Advanced Tools Utilizing advanced scheduling tools and techniques can significantly elevate the execution phase. Successful turnarounds often employ digital tools that allow for real-time updates and adjustments, aiding in managing the critical path effectively. This real-time capability ensures that any deviations from the schedule are promptly addressed, keeping the project timeline intact. Cost Management and Optimization Cost control is another critical aspect. Projects that have excelled in cost management utilized thorough cost estimation during the initial turnaround planning. By identifying potential cost-saving opportunities early, these projects were able to optimize resource allocation without compromising on quality or safety. Team Collaboration and Communication Turnarounds are complex, involving multiple stakeholders. Successful cases point to open communication channels and collaborative work environments as key factors in achieving project goals. Regular meetings and feedback loops help in keeping all parties informed and engaged, promoting a sense of ownership and accountability throughout different process phases. By dissecting these successful turnarounds, it's clear that a combination of careful scope definition, safety prioritization, technological integration, vigilant cost management, and effective communication forms the backbone of robust turnaround management practices. As the industry evolves, learning from these examples continues to shape future trends and strategies.Future Trends in Turnaround Planning

Embracing Innovation in Turnaround Practices

In the ever-evolving landscape of turnaround management, integrating innovative practices is essential for staying ahead. The role of technology and cutting-edge methodologies cannot be understated when aiming for a successful turnaround process. Companies are increasingly looking toward data analytics and AI-driven insights to fine-tune their turnaround planning. By harnessing these tools, maintenance planners can predict potential equipment failures, effectively aligning maintenance schedules with real-time operational data.

Adopting Real-Time Scheduling Tools

Real-time scheduling tools are becoming pivotal in turnaround scheduling. By incorporating dynamic scheduling applications, project managers can react swiftly to unexpected changes during the execution phase. This proactive approach minimizes downtime and ensures that safety protocols are maintained, aligning the scope with overall project timelines. Moreover, the flexibility provided by these tools ensures that shutdowns are well-coordinated, adhering to cost-effective and timely project management.

Pushing Towards Green and Sustainable Turnarounds

With growing emphasis on sustainability, turnarounds are increasingly adopting eco-friendly practices. Future turnaround efforts aim to diminish their carbon footprint through efficient shutdown strategies and resource optimization. A plant turnaround now not only focuses on maintenance and execution but also on long-term environmental impact. By incorporating sustainable methods, businesses not only align with global standards but also improve their brand equity in the marketplace.

Enhancing Collaboration Through Digital Platforms

The digital shift has set the stage for enhanced collaboration in turnaround maintenance. Cloud-based platforms enable seamless coordination among maintenance managers, plant operators, and external vendors. By facilitating better visibility across the board, these digital platforms aid in the accurate allocation of resources and execution within turnaround projects. Innovative digital solutions are empowering teams to streamline communication channels, which is critical for managing work orders and executing scope work efficiently.

Prioritizing Safety Standards

Safety remains at the forefront of turnaround efforts. Future trends emphasize more rigorous safety assessments and risk management strategies. Integrating advanced AI-driven safety techniques ensures more comprehensive oversight during the planning phase. A focus on safety not only minimizes risk during turnarounds but also reassures stakeholders of the company's commitment to maintaining safe operations.